The 3D Printing Revolution How 2024 is Changing the Game

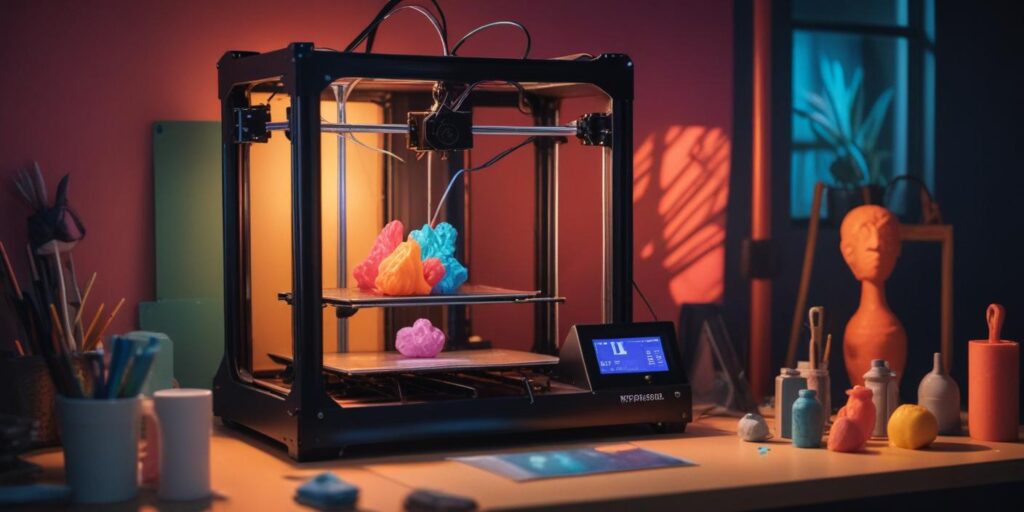

Remember when 3D printing was just for prototypes and futuristic gadgets? Those days are long gone. We’re living in a world where 3D printing is exploding in popularity, transforming industries from healthcare to construction. Buckle up, because 2024 is shaping up to be a pivotal year for this revolutionary technology.

From Experimental to Essential The Shift to Mass Production

The numbers don’t lie. The global 3D printing market reached a whopping $22.14 billion in 2023 – that’s a massive leap of 26.8% from the year before. Experts predict it’ll hit $24.8 billion by the end of 2024 and skyrocket to $57.1 billion by 2028. But here’s the real game-changer: we’re moving beyond prototypes. Businesses are waking up to the power of 3D printing for actual production runs.

Think about it. Imagine printing 1,000 intricate parts with the same ease as printing a single prototype. That’s the reality more and more companies are facing. In fact, there’s been a noticeable jump in the number of businesses using 3D printing to churn out over 1,000 parts. The future of manufacturing is here, and it’s all about agility, efficiency, and pushing the boundaries of what’s possible.

At our own company, we’ve fully embraced the power of 3D printing to offer our customers the best possible solutions. We’re constantly exploring innovative ways to integrate this technology into our services, so we can help businesses of all sizes unlock their full potential in this exciting new era of manufacturing. You can find out more about how we’re using 3D printing to revolutionise manufacturing right here on our website.

Why 3D Printing is Winning The Advantages are Clear

So, what’s driving this widespread adoption of 3D printing? For starters, it’s fast becoming the secret weapon for businesses that need to move quickly. A recent survey found that a staggering 47% of companies choose 3D printing because it slashes lead times. Time is money, after all.

And then there’s the unbeatable design freedom. 3D printing laughs in the face of complexity. It empowers engineers and designers to create intricate geometries and organic shapes that were simply unimaginable with traditional manufacturing methods. This opens up a world of possibilities for innovation, allowing companies to create products that are not only functional but also aesthetically stunning.

But it’s not just about speed and design. Cost-effectiveness plays a huge role, too. As 3D printing technology matures, it’s becoming increasingly affordable. In fact, a whopping 82% of businesses report significant cost savings when they incorporate 3D printing into their manufacturing processes. And let’s not forget the allure of customization. 3D printing allows businesses to cater to individual customer needs, creating bespoke products that stand out in a crowded marketplace.

A Glimpse into the Future Trends Shaping 3D Printing

The world of 3D printing is constantly evolving. New materials, groundbreaking technologies, and innovative applications are popping up all the time. Here are a few key trends to keep your eye on:

- Materials Matter: We’re witnessing a surge in the development of high-performance materials designed specifically for 3D printing. Think super-strong polymers, lightweight metals, and even biocompatible materials for medical implants. This opens up a world of possibilities for creating products that are lighter, stronger, and more durable than ever before.

- AI is Joining the Party: Artificial intelligence (AI) is poised to revolutionize the 3D printing process. AI-powered software can optimize designs, predict potential problems before they even arise, and even control printers in real time. This means faster production, less waste, and ultimately, more efficient and cost-effective manufacturing.

- Industry Disruption is Coming: 3D printing is making waves across a wide range of industries. In healthcare, it’s being used to create everything from custom prosthetics to intricate surgical models. The construction industry is exploring large-scale 3D printing for building houses and other structures, and the possibilities for aerospace, automotive, and consumer goods are practically limitless.

- Medical Marvels: A staggering 77% of experts believe that healthcare will be the industry most profoundly impacted by 3D printing. Imagine a world where surgeons can practice complex procedures on 3D-printed replicas of a patient’s organs or where personalized prosthetics are created in a matter of hours. That’s the power of 3D printing in medicine.

- Construction Gets a Makeover: Forget about traditional building methods. 3D printing is set to revolutionize how we construct houses and other structures. With 44% of experts predicting major disruption in this field, we’re on the cusp of seeing faster, cheaper, and more sustainable construction methods thanks to the power of 3D printing.

Beyond Prototyping: 3D Printing Takes Center Stage in Production with Companies Like Protolabs

The story of 3D printing’s rise wouldn’t be complete without mentioning companies like Protolabs, a leading digital manufacturer known for its rapid prototyping and on-demand production services. They’ve been at the forefront of this revolution, offering a wide range of 3D printing technologies and materials to meet the evolving needs of their customers. Their commitment to innovation and speed has made them a go-to resource for businesses looking to leverage the power of 3D printing for everything from prototypes to end-use parts. If you’re looking for a reliable partner to guide you through the world of 3D printing, Protolabs is definitely worth checking out. You can visit their website here to learn more about their services.

The ability of companies like Protolabs to provide high-quality, custom-designed parts on demand is a game changer for industries ranging from aerospace and automotive to medical devices and consumer products. Protolabs and similar companies are enabling businesses to innovate faster, get their products to market quicker, and stay ahead of the competition in an increasingly demanding global marketplace. And for those seeking similar services, we are proud to offer a range of solutions that rival even the industry giants.

Customization and Personalization: The Power of One

One of the most exciting aspects of 3D printing is its ability to break free from the limitations of mass production and embrace the era of personalization. Imagine a world where you can order a pair of shoes perfectly tailored to your foot shape, a bicycle helmet designed to match your head measurements, or even a hearing aid customized to fit the unique contours of your ear canal.

This level of customization is where 3D printing truly shines. It empowers businesses to create products that are no longer confined to standard sizes, shapes, or designs. This opens up a world of possibilities, particularly in industries like healthcare, where personalized medicine and patient-specific treatments are becoming increasingly important.

And it’s not just about functionality. Customization extends to aesthetics as well. Consumers are no longer content with mass-produced, one-size-fits-all products. They crave unique items that reflect their individual style and personality. 3D printing allows businesses to cater to this desire for personalization, offering customized designs, colors, and even engravings that transform everyday products into one-of-a-kind creations.

A Greener Shade of Manufacturing: 3D Printing’s Sustainable Side

In an era of increasing environmental awareness, sustainability is no longer a buzzword; it’s a necessity. And here’s where 3D printing steps up to the plate, offering a greener alternative to traditional manufacturing processes.

| Pros | Cons |

|---|---|

| Reduced Waste | Material Limitations |

| Lower Energy Consumption | Post-Processing Challenges |

| On-Demand Production | Scalability Issues |

One of the most significant environmental benefits of 3D printing is its potential to drastically reduce waste. Unlike subtractive manufacturing, where materials are cut away and discarded, 3D printing is an additive process. Material is only deposited where it’s needed, minimizing waste and making it an ideal choice for eco-conscious businesses.

But it doesn’t stop there. 3D printing also consumes less energy compared to traditional manufacturing methods. It requires less transportation of goods and often uses materials that can be recycled or biodegraded. And because 3D printing enables on-demand production, businesses can produce products only when needed, reducing the need for large inventories and minimizing waste associated with overproduction.

The 3D printing revolution is here, and it’s changing the world one layer at a time. From streamlining production processes to empowering businesses to create personalized products, the possibilities are endless. As we venture further into 2024 and beyond, one thing is certain: 3D printing is poised to transform industries, disrupt traditional business models, and shape a future where innovation knows no bounds.